STEP 4

Due to the combustion nature of the hydrogen, the ignition system also needs to be converted, depending on what you have as a starting point, you have to do it in different ways.[1]

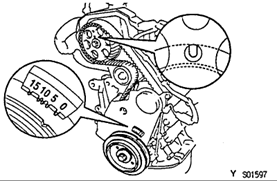

You can sum it up by saying that the ignition timing at high engine speeds with an internal combustion engine converted for hydrogen should be later than, for example, with traditional gasoline operation, where the ignition timing is approximately 25-35 degrees before top dead center. On the hydrogen converter, the ignition timing can be close to zero at high engine speeds, because the flame speed is so high.

On the other hand, the flame speed decreases with a leaner mixture, which for example occurs at low rpm, for example at idle, but also at low load, on the petrol engine the ignition timing is around 10 degrees before top dead center, when instead on the hydrogen converted engine it should be a little earlier ignition timing to burn the entire mixture.

This modification could be done by modifying the software in the vehicle's control unit according to the desired ignition timings you want to access in the different conditions the engine will be exposed to.

On an older engine with a traditional distributor that runs at the speed of the camshaft, you could instead use a distributor that is in the opposite direction to the one that should be there, which would then mean that the ignition timing is lowered at higher rpm and raised at lower rpm, such as idle.

Furthermore, spark plugs with a platinum coating should not be used because the platinum acts as a catalyst between hydrogen and oxygen and the risk of self-ignition can then occur.

When planning to convert a regular internal combustion engine that previously ran on fossil fuel containing carbon, it is extremely important to dismantle all parts in and on the engine that may contain soot particles. The cylinder head must be disassembled to access the soot that usually occurs in the combustion chamber. The valves should also be taken out so that they too can be cleaned of soot, also inside the ports, especially on the exhaust side, all soot particles should be removed. Up on the piston tops, there are usually soot deposits that must be removed.

All this work is important to do in order to counteract self-ignition that will occur if there are residual soot particles that glow. From the hydrogen, there will not be any soot deposits later because it does not contain any carbon in it or oxygen.

[1](Verhelst and Wallner, 2009)