PRESSURE TANKS

Hydrogen pressure tanks are containers that are designed to store hydrogen gas at high pressure. They are often made of composite materials such as carbon fiber or fiberglass, which are lightweight and strong enough to withstand the pressure of the gas inside the tank.

Hydrogen gas is stored in pressure tanks in order to increase the amount of gas that can be stored in a given volume. When hydrogen is stored at high pressure, its energy density increases, which allows it to take up much less space. This makes it possible to store large amounts of hydrogen in a relatively small tank, making it an attractive option for use in fuel cell vehicles and other applications where space is limited.

There are several types of hydrogen pressure tanks, including those that are designed to be refilled, and those that are designed to be disposed of after they are emptied. Some tanks are also designed to be used in combination with other types of storage systems, such as cryogenic tanks, which are, used to store hydrogen in liquid form at very low temperatures.

In order to ensure the safety of the gas inside the tank, hydrogen pressure tanks are equipped with various safety features such as pressure relief valves and burst discs. These features help to prevent the tank from rupturing or bursting in the event of an overpressure situation.

Overall, hydrogen pressure tanks are an important part of the infrastructure needed to store and transport hydrogen gas, and they play a critical role in the development and deployment of hydrogen fuel cell technologies.

Pressure vessels can be used both for stationary storage and for mobile hydrogen storage. For static applications, seamless steel cylinders made of low carbon or alloy steel are usually used. They are produced in a wide range of volumes according to the planned use.

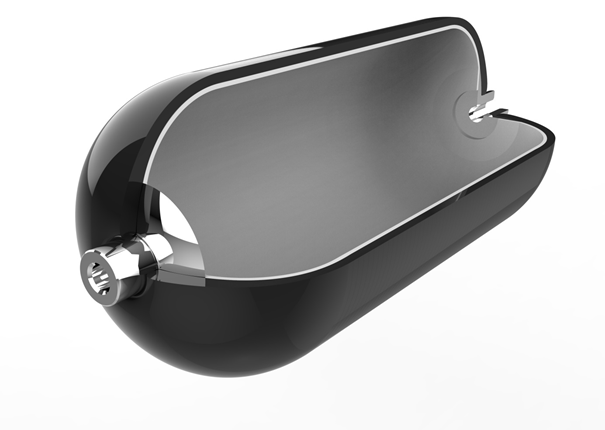

With mobile applications, composite pressure vessels are usually used. They are made in volumes ranging from tens of liters up to roughly 300 l. A typical operating pressure is 350 bar, in the newest applications from 450 up to 700 bar (temporary technological limit is 1000 bar).

Cyllinders 12 meters long with outer diameter of approximately 80 cm can be used as tanks for filling stations of hydrogen-fueled vehicles or as tanks for energy surplus from renewable energy (Vodíková strategie České republiky, 2021, s. 111).

The fact that it is a tested technology which is verified and meets all rising requirements on hydrogen storage is considered an advantage. It is suitable for storage of low-scale amount in irregular supplies. With development of hydrogen technologies, the hydrogen storage conditions are going to increase dramatically. One question remains, if the current evolution of technologies will not cause a decline in storage needs and high pressure hydrogen transportation. A disadvantage of pressure tanks can be their safety aspects and technological limits as for example pressure, material or volume of pressure cylinders (Vodíková strategie České republiky, 2021, s. 111-112).