CLASSIFICATION BY HYDROGEN SOURCE

1) Hydrogen filling stations without their own hydrogen source

2) Hydrogen filling stations with their own hydrogen source

Most filling stations are built in locations where there are no suitable hydrogen sources and hydrogen has to be transported to these stations. Hydrogen filling stations with their own hydrogen source should be built at hydrogen production sites (e.g. production from landfill gas, hydrogen as a waste gas from chemical production, etc.). By building hydrogen filling stations at these locations, a considerable amount of costs associated with transporting the hydrogen and filling it into transport containers are saved. The disadvantage is that it is usually less accessible to the public. Therefore, this type of filling station is particularly suitable for local customers or for filling vehicles that operate in the production of this type of hydrogen.

Currently, the most common type of hydrogen filling station is for compressed hydrogen gas. These stations are stationary and similar in design to CNG filling stations. The filling pressure is set at 700 bar for passenger cars and 350 bar for trucks. In most of the refuelling stations already implemented, hydrogen is imported in tanks and is then pumped into a storage tank in the refuelling station.

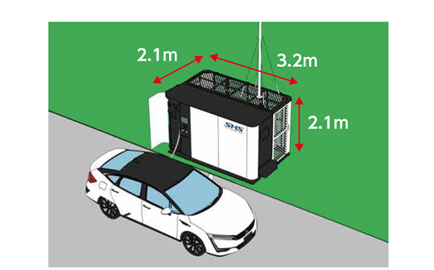

As a point of interest, here is an example of a small hydrogen filling station which, thanks to the technology used and its small size, is very well suited for example to dense urban areas. Honda has quite a long history with hydrogen cars, with the first FCX clarity model appearing on the market back in 2007. At the same time, it has also spent a long time developing a better hydrogen refueling station. In 2014, the first prototype SHS station appeared - a station that houses everything needed to produce hydrogen in the smallest possible space. In 2015, it came up with a revolutionary technology for hydrogen production using high-pressure electrolysis with its own device called the Power Creator. The SHS station is a very compact way to, produce, store and refill hydrogen, all with only a connection to water and electricity. The energy supplied is expected to be mainly from renewable sources, thus reducing CO2 emissions even when producing hydrogen. By using the power creator system, high pressure hydrogen is produced and therefore there is no need to use compressors which take up space and thus the electricity consumption of the whole plant is also reduced, according to the Honda website the electricity consumption has been reduced to 1/4. At the same time there is no need for such large tanks to store more hydrogen. All these improvements have made it possible for the station to occupy a space of 3.7m x 2.25m x 2.57m and can be placed almost anywhere.