CONTROLLED RELUCTANCE MOTOR

Reluctance motors are based on the long-known technique of reluctance stepper motors, where changes in magnetic conductivity are utilized depending on the position of the rotor. Although reluctance stepper motors can be produced easily and inexpensively, they have seen limited use for many decades due to their non-uniformity, meaning the torque depends on the rotor position. This disadvantage can be overcome through appropriate control.

There are two main types of reluctance motors: one based on the principle of a synchronous machine with salient poles and the other referred to as a switched reluctance motor, which is based on an electromechanical converter. The first type is a synchronous machine without a field winding and a rotor that has been modified to vary magnetic conductivity as much as possible. Switched reluctance motors are unique in that they cannot function without the aid of electronic circuits, unlike other electrical machines. Depending on the control method used, they can operate in step mode or continuous rotation mode."

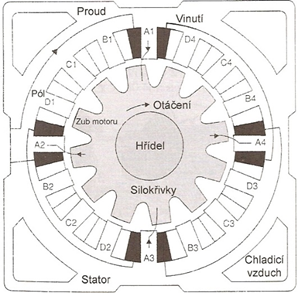

A reluctance motor is a special type of AC motor. There are simple coils on the stator powered by voltage of one polarity. There is no field winding or sliding contacts in its rotor. The soft iron rotor has gear-shaped pole extensions.

The principle is that after current is introduced into the corresponding coils, the rotor is adjusted so that the magnetic circuit has minimum magnetic resistance. The speed and torque of the reluctance motor can be very well influenced by power electronics. A reluctance motor starts asynchronously and then runs synchronously.

The concept of reluctance refers to the magnetic resistance that the rotor represents in the magnetic field. Due to the massless tooth gaps in the rotor, the reluctance motor rotor has a very small moment of inertia and thus very high acceleration possibilities.

Advantages of reluctance motors:

• high torque at low speeds

• high efficiency

• robust construction

• low maintenance costs

• stable operation of the motor when one or more phases fail

• high overload capacity and low heat production

• high efficiency and favorable price

Disadvantages of reluctance motors:

• the torque is not uniform (pulsating torque)

• higher noise emissions

• it has high demands on the control and power parts at high speeds